What Processing Capabilities Mean for Efficient Melamine Foam Conversion

2025-07-10

What Makes Melamine Foam So Unique in Structure and Properties?

Melamine foam is a highly adaptable open-cell material made from melamine resin. Its tiny structure forms a light but sturdy framework. This gives it great heat-blocking, sound-soaking, and fire-resistant traits. The foam’s linked polymer network creates small air pockets. These pockets trap sound waves and heat, making it perfect for both industrial and home uses.

The foam feels soft but has a firm core. This lets it be pressed, shaped, or cut without breaking apart. It stays stable during shaping processes. Also, the foam is safe and resists wearing out over time. This ensures it works well for a long time in different settings.

Where Can You Use Melamine Foam in Everyday and Industrial Settings?

Melamine foam appears in many industries because of its useful features. In buildings, it’s used as soundproofing panels to cut down noise. In transportation, like trains and planes, it blocks heat while meeting tough fire safety rules.

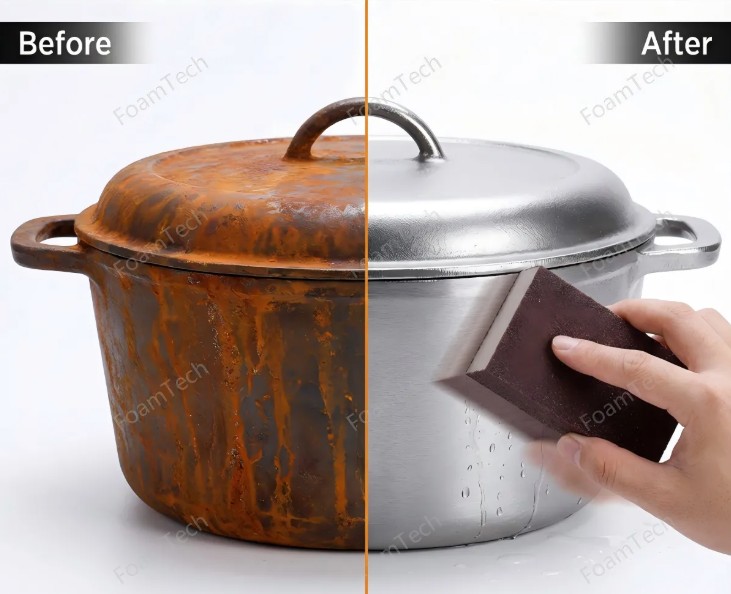

For everyday use, melamine foam is famous as a cleaning sponge, often called a “magic eraser.” Its tiny, rough surface removes dirt without chemicals. It’s also used in HVAC systems to filter air and in electronics to reduce shaking. The foam’s flexibility comes from how well it handles precise shaping methods.

Why Do Processing Capabilities Matter in Foam Conversion?

The performance of melamine foam depends heavily on how it’s shaped. Even the best foam won’t work well if it’s not cut or treated properly. Poor processing can ruin its effectiveness.

Processing Capabilities affect not just how the foam looks but also how it works. For example, bad cuts can cause air leaks in insulation or uneven surfaces in sound panels. Proper shaping ensures the foam fits perfectly, bonds well with other materials, and lasts under stress or heat changes.

Which Parameters Are Crucial During Foam Conversion?

When turning melamine foam into useful parts, certain factors must be carefully managed:

- Cutting accuracy: Sizes must be exact, sometimes within tiny fractions of an inch.

- Compression level: Pressing too hard can ruin the foam’s open-cell design.

- Surface quality: Damage during handling hurts sound or heat-blocking abilities.

- Heat control: Some processes use heat. Managing temperature prevents foam damage.

These elements make advanced Processing Capabilities vital for working with melamine foam.

What Are the Main Techniques Used to Cut and Shape Melamine Foam?

To meet different project needs—from small test runs to large-scale production—several cutting methods are used for melamine foam.

How Does CNC Cutting Deliver Precision Parts for Specialized Applications?

CNC (Computer Numerical Control) cutting is great for making detailed shapes or parts with tight measurements. A computer guides the machine to cut exact sizes. This ensures every piece is consistent, even for complex designs. CNC tools can cut flat or 3D shapes without harming the foam’s delicate structure.

This method shines in fields like aerospace or cars, where precision is critical. CNC cutting also reduces waste and keeps results steady, making it cost-effective for big projects.

Why Is Die-Cutting Preferred for Efficient Mass Production?

Die-cutting uses shaped metal tools, called dies, to press against foam sheets. This creates identical shapes quickly. It’s ideal for making thousands of pieces, like gaskets, seals, or filter parts.

FoamTech offers professional die-cutting services. They ensure smooth edges and even thicknesses across large batches. This method saves time while keeping quality high for industrial clients.

What Surface Treatments Can Enhance Melamine Foam Functionality?

Beyond cutting, surface changes play a big role in making the foam work better for specific tasks.

How Do Lamination and Coating Improve Durability and Compatibility?

Adding layers, like films or foils, to melamine foam can make it resist water or reflect heat. Coatings can add germ-fighting layers for medical uses or conductive films for electronics protection.

These changes let the foam work in tougher settings without losing its core strengths.

Why Consider Embossing or Texturing When Designing Functional Surfaces?

Embossing adds patterns to the foam’s surface. This can improve grip for cleaning tools, spread sound better in panels, or make products look nicer in home designs.

Texturing also helps the foam stick better to glues during assembly. This small change boosts product reliability.

How Does Advanced Equipment Improve Quality During Conversion?

Modern tools allow faster production while keeping measurements precise—something handwork can’t always do.

What Role Does Automation Play in Customizing Melamine Foam Products?

Automation ensures steady results and speed. Whether making a few test pieces or thousands of units weekly, automated systems keep every piece perfect.

You can also use software to switch designs quickly. This is great for clients needing different products from one supplier.

Why Is High-Precision Machinery Essential for Consistent Results?

High-precision tools cut down on mistakes. They handle tricky tasks like adding multiple layers or cutting complex shapes on soft foam. With these machines, products not only look good but work better in real-world use.

Who Offers Reliable Expertise in Converting Melamine Foam Professionally?

For a partner with deep knowledge and strong Processing Capabilities, FoamTech stands out. Based in Zhejiang, this company specializes in shaping nano-scale foams, including melamine, for many industrial uses.

FoamTech provides die-cutting services tailored to client needs, from exact sizes to complex shapes. They also offer finishing options like layering and patterning. Whether you’re making car parts or building sound panels, they deliver steady quality at scale with modern tools and a skilled team.

Their focus on custom solutions makes them more than a supplier—they’re a partner in creating innovative, reliable products.

What Should You Look For When Choosing a Foam Processing Partner?

Choosing the right converter is about more than cost—it’s about lasting value.

Why Do Technical Expertise and Equipment Range Matter So Much?

You need a partner who knows how foams react to pressure, heat, or cutting. They should have tools built for those conditions. A wide range of equipment means they can adapt to your designs without needing new suppliers mid-project.

How Do You Ensure Material Compatibility and Quality Assurance Standards Are Met?

Ask about testing: Do they check size accuracy? Surface smoothness? Bonding strength after layering? A good converter has quality checks that meet global standards. This ensures every delivery matches your expectations, even for big orders.

Why Is Zhejiang FoamTech an Ideal Choice for Your Next Project?

Here’s why FoamTech is a top pick for melamine foam projects.

How Has Their Die-Cutting Experience Delivered Proven Results Across Industries?

With years of expertise, FoamTech has mastered die-cutting. They ensure precise measurements on soft foams like melamine while scaling up for clients in aerospace, medical, and other fields.

What Sets Their Approach Apart in Terms of Precision and Innovation?

FoamTech doesn’t just deliver what you ask for—they improve it. They invest in new tools, test materials thoroughly, and offer design advice to make your products perform better through smarter shaping methods.

FAQ

Q1: Can die-cutting be used on all types of foams, including nano-scale ones?

A: Yes. FoamTech confirms their die-cutting services work well for nano-scale materials like melamine foam. They use special tools to keep shapes intact during fast production.

Q2: What customization options are available when ordering processed melamine foam?

A: You can choose specific shapes through CNC or die-cutting. You can also add surface changes like layering, patterning, or texturing for needs like water resistance or better grip.

Q3: Does processing affect the fire-resistance properties of melamine foam?

A: Not if done right. Proper shaping methods protect the foam’s fire-resistant traits by avoiding too much heat during cutting or treatment.

What Makes Melamine Foam So Unique in Structure and Properties?

Melamine foam is a highly adaptable open-cell material made from melamine resin. Its tiny structure forms a light but sturdy framework. This gives it great heat-blocking, sound-soaking, and fire-resistant traits. The foam’s linked polymer network creates small air pockets. These pockets trap sound waves and heat, making it perfect for both industrial and home uses.

The foam feels soft but has a firm core. This lets it be pressed, shaped, or cut without breaking apart. It stays stable during shaping processes. Also, the foam is safe and resists wearing out over time. This ensures it works well for a long time in different settings.

Where Can You Use Melamine Foam in Everyday and Industrial Settings?

Melamine foam appears in many industries because of its useful features. In buildings, it’s used as soundproofing panels to cut down noise. In transportation, like trains and planes, it blocks heat while meeting tough fire safety rules.

For everyday use, melamine foam is famous as a cleaning sponge, often called a “magic eraser.” Its tiny, rough surface removes dirt without chemicals. It’s also used in HVAC systems to filter air and in electronics to reduce shaking. The foam’s flexibility comes from how well it handles precise shaping methods.

Why Do Processing Capabilities Matter in Foam Conversion?

The performance of melamine foam depends heavily on how it’s shaped. Even the best foam won’t work well if it’s not cut or treated properly. Poor processing can ruin its effectiveness.

Processing Capabilities affect not just how the foam looks but also how it works. For example, bad cuts can cause air leaks in insulation or uneven surfaces in sound panels. Proper shaping ensures the foam fits perfectly, bonds well with other materials, and lasts under stress or heat changes.

Which Parameters Are Crucial During Foam Conversion?

When turning melamine foam into useful parts, certain factors must be carefully managed:

- Cutting accuracy: Sizes must be exact, sometimes within tiny fractions of an inch.

- Compression level: Pressing too hard can ruin the foam’s open-cell design.

- Surface quality: Damage during handling hurts sound or heat-blocking abilities.

- Heat control: Some processes use heat. Managing temperature prevents foam damage.

These elements make advanced Processing Capabilities vital for working with melamine foam.

What Are the Main Techniques Used to Cut and Shape Melamine Foam?

To meet different project needs—from small test runs to large-scale production—several cutting methods are used for melamine foam.

How Does CNC Cutting Deliver Precision Parts for Specialized Applications?

CNC (Computer Numerical Control) cutting is great for making detailed shapes or parts with tight measurements. A computer guides the machine to cut exact sizes. This ensures every piece is consistent, even for complex designs. CNC tools can cut flat or 3D shapes without harming the foam’s delicate structure.

This method shines in fields like aerospace or cars, where precision is critical. CNC cutting also reduces waste and keeps results steady, making it cost-effective for big projects.

Why Is Die-Cutting Preferred for Efficient Mass Production?

Die-cutting uses shaped metal tools, called dies, to press against foam sheets. This creates identical shapes quickly. It’s ideal for making thousands of pieces, like gaskets, seals, or filter parts.

FoamTech offers professional die-cutting services. They ensure smooth edges and even thicknesses across large batches. This method saves time while keeping quality high for industrial clients.

What Surface Treatments Can Enhance Melamine Foam Functionality?

Beyond cutting, surface changes play a big role in making the foam work better for specific tasks.

How Do Lamination and Coating Improve Durability and Compatibility?

Adding layers, like films or foils, to melamine foam can make it resist water or reflect heat. Coatings can add germ-fighting layers for medical uses or conductive films for electronics protection.

These changes let the foam work in tougher settings without losing its core strengths.

Why Consider Embossing or Texturing When Designing Functional Surfaces?

Embossing adds patterns to the foam’s surface. This can improve grip for cleaning tools, spread sound better in panels, or make products look nicer in home designs.

Texturing also helps the foam stick better to glues during assembly. This small change boosts product reliability.

How Does Advanced Equipment Improve Quality During Conversion?

Modern tools allow faster production while keeping measurements precise—something handwork can’t always do.

What Role Does Automation Play in Customizing Melamine Foam Products?

Automation ensures steady results and speed. Whether making a few test pieces or thousands of units weekly, automated systems keep every piece perfect.

You can also use software to switch designs quickly. This is great for clients needing different products from one supplier.

Why Is High-Precision Machinery Essential for Consistent Results?

High-precision tools cut down on mistakes. They handle tricky tasks like adding multiple layers or cutting complex shapes on soft foam. With these machines, products not only look good but work better in real-world use.

Who Offers Reliable Expertise in Converting Melamine Foam Professionally?

For a partner with deep knowledge and strong Processing Capabilities, FoamTech stands out. Based in Zhejiang, this company specializes in shaping nano-scale foams, including melamine, for many industrial uses.

FoamTech provides die-cutting services tailored to client needs, from exact sizes to complex shapes. They also offer finishing options like layering and patterning. Whether you’re making car parts or building sound panels, they deliver steady quality at scale with modern tools and a skilled team.

Their focus on custom solutions makes them more than a supplier—they’re a partner in creating innovative, reliable products.

What Should You Look For When Choosing a Foam Processing Partner?

Choosing the right converter is about more than cost—it’s about lasting value.

Why Do Technical Expertise and Equipment Range Matter So Much?

You need a partner who knows how foams react to pressure, heat, or cutting. They should have tools built for those conditions. A wide range of equipment means they can adapt to your designs without needing new suppliers mid-project.

How Do You Ensure Material Compatibility and Quality Assurance Standards Are Met?

Ask about testing: Do they check size accuracy? Surface smoothness? Bonding strength after layering? A good converter has quality checks that meet global standards. This ensures every delivery matches your expectations, even for big orders.

Why Is Zhejiang FoamTech an Ideal Choice for Your Next Project?

Here’s why FoamTech is a top pick for melamine foam projects.

How Has Their Die-Cutting Experience Delivered Proven Results Across Industries?

With years of expertise, FoamTech has mastered die-cutting. They ensure precise measurements on soft foams like melamine while scaling up for clients in aerospace, medical, and other fields.

What Sets Their Approach Apart in Terms of Precision and Innovation?

FoamTech doesn’t just deliver what you ask for—they improve it. They invest in new tools, test materials thoroughly, and offer design advice to make your products perform better through smarter shaping methods.

FAQ

Q1: Can die-cutting be used on all types of foams, including nano-scale ones?

A: Yes. FoamTech confirms their die-cutting services work well for nano-scale materials like melamine foam. They use special tools to keep shapes intact during fast production.

Q2: What customization options are available when ordering processed melamine foam?

A: You can choose specific shapes through CNC or die-cutting. You can also add surface changes like layering, patterning, or texturing for needs like water resistance or better grip.

Q3: Does processing affect the fire-resistance properties of melamine foam?

A: Not if done right. Proper shaping methods protect the foam’s fire-resistant traits by avoiding too much heat during cutting or treatment.