Material Science Perspective on the Advantage of Tri-Layer Melamine Sponges

2025-12-11

Tri-layer melamine sponges stand out as a better choice than old cleaning tools. They mix strong materials with smart design changes. This setup gives them good strength, heat resistance, and even scratch power. As a result, they work well in factory jobs and careful cleaning tasks. This piece looks at how material science boosts the use and money value of these sponges.

If you need tough cleaning tools from smart engineering and steady quality, check out FoamTech. It focuses on melamine sponge tech. The company has a full R&D and manufacturing background. Plus, it provides custom product making, OEM services, and solid shipping help.

Structural Advantages Boosting Mechanical Performance & Stability

FoamTech’s Tri-Layer Sandwich Melamine Sponge stands out for its innovative structural design. By integrating melamine foam with a PU backing, it achieves enhanced strength, flexibility and abrasive efficiency, while maintaining excellent thermal and chemical stability even under harsh cleaning conditions.

Structural Composition Enhances Mechanical Performance

The tri-layer sponge joins melamine foam with a polyurethane (PU) backing layer. This makes a tough structure. It boosts pull strength, bounce-back, and size steadiness under force. Melamine sponges have up to 99% open space. Each hole size stays between 5–20 microns. This helps cleaning work well. It also keeps the shape strong.

By mixing these materials, the sponge cuts down on rips and shape changes. Even in rough cleaning, it holds up. The Tri-Layer Sandwich Melamine Sponge fits for many uses. It avoids splitting or breaking. So, it gives better last power and sure work in hard spots.

Layer Integration Improves Abrasive Efficiency

A sponge's power to remove dirt relies on how it touches the surface and spreads push. The melamine layer works at tiny scale. It gives small scratch cleaning that picks up bits without harm. This material comes from melamine-formaldehyde resin. It goes through a special foam process. Its special 3D web shape has made a fresh cleaning way. It uses "physical rub instead of chemical break-down".

The PU layer helps spread force evenly over the sponge face. This boosts touch power. It also stops too much wear at one spot. The Tri-Layer Sandwich Melamine Sponge uses a smart join method. All layers team up. Thus, it keeps steady scratch work.

Thermal and Chemical Stability Under Harsh Conditions

In factory cleaning, sponges face heat and chemicals often. Melamine foam handles heat well. It keeps its strength even with rub heat. Its fire-stop power hits UL94 V-0 level. When in open fire, it makes a thick burned layer. No melt drops form.

The PU support layer fights off break from solvents and cleaning chemicals. Corrosion-resistant type: It takes pH1-14 acid and alkali spots. It fits for cleaning chemical plant gear. These traits keep the sponge steady in factory cleaning places.

Functional Benefits in Precision Cleaning Applications

Top sponges do more than clean. They fit soft surfaces, easy hold needs, and long use hopes.

Controlled Abrasion for Sensitive Surfaces

Many costly surfaces need no-scratch clean ways. Melamine foam's even hole size gives steady scratch without harm to covers or soft stuff. Tests from German TÜV lab show its rub number on car paint is just 0.15. That's way less than 0.42 for an old scrub pad. So, tri-layer sponges suit electronics, car insides, and lab care.

Enhanced Grip and Handling During Use

The PU backing layer adds easy-hold perks. It gives better hold in hand work. Users can push just right. It cuts tiredness in long jobs. FoamTech makes its sponges for pro use spots. This includes factory flows.

Extended Lifespan Reduces Replacement Frequency

Last power matters in money-tight jobs. Strong join between layers stops split in many uses. The thick foam fights squeeze. It keeps shape over cleaning rounds. High-quality items have density between 40–60kg/m³.

Comparative Advantage Over Single-Layer Sponges

Old melamine sponges may start strong. But they miss the build support for long use.

Structural Weaknesses of Traditional Melamine Sponges

One-layer setups break early from no support. Single-layer sponges lack strength boost. This leads to quick wear. They bend easy under long push or hard scrub jobs.

Performance Degradation in Single-Layer Designs

Without PU backing to spread force, one-layer melamine sponges get uneven wear. This cuts their life. It drops work over time. The tri-layer setup keeps steady power. It does this with better force handle and material stick.

Cost-Efficiency Through Longevity and Reliability

Start costs may run higher. Yet tri-layer sponges give better worth. They cut change needs. Less change means lower stuff use and work costs. Their strong build keeps clean power all through life.

Role of Material Interfaces in Multi-Layer Sponge Design

How layers touch sets how well tri-layer sponges work in real jobs.

Adhesion Techniques Between Layers Determine Durability

Last power ties right to layer stick. New join ways keep build together under push. FoamTech uses its own stick tech. This stops split in use.

Mechanical Synergy Between Layers Enhances Functionality

Each layer picks for its job. Melamine for scratch. PU for bend and strength. When built right, layers team up. This lifts full work past single parts.

Stress Distribution Across Layers Minimizes Wear Points

A many-layer build spreads push even. It skips spot harm that cuts life early. Good design gives longer use. Even in rough spots.

Application Versatility Across Industrial Sectors

Tri-layer melamine sponges shine in many fields. They adapt well and fight chemicals.

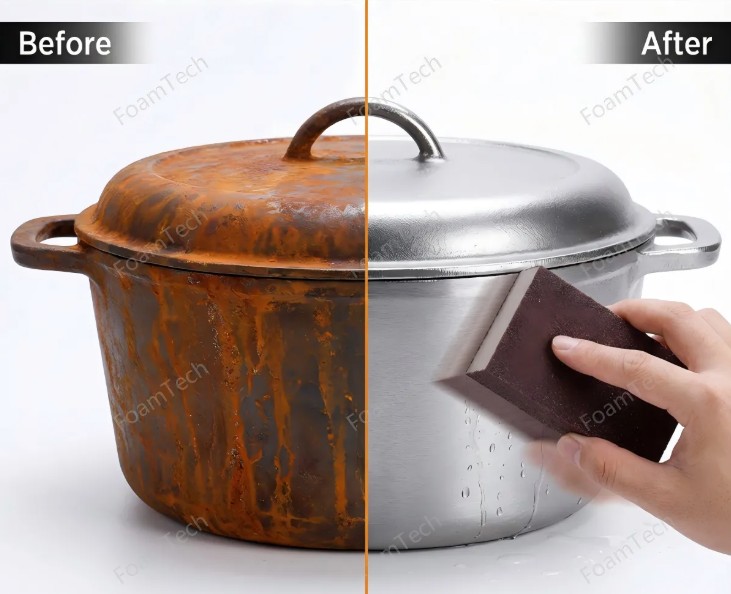

Suitability for Heavy-Duty Cleaning Tasks

They clean grease, rust, and paint bits well. No harm to base stuff. Uses go from kitchen shops to car clean.

Compatibility with Various Cleaning Agents

These sponges hold shape with alcohols, fat removers, or acid/base cleaners. They stand up to alcohols, soaps, fat removers in pro care.

Use Cases in Specialized Environments

In clean rooms or electronics lines, where bits must stay low, custom types work best. Antistatic type: Surface resistance 10^6-10^9Ω. It fits for cleaning electronic shops.

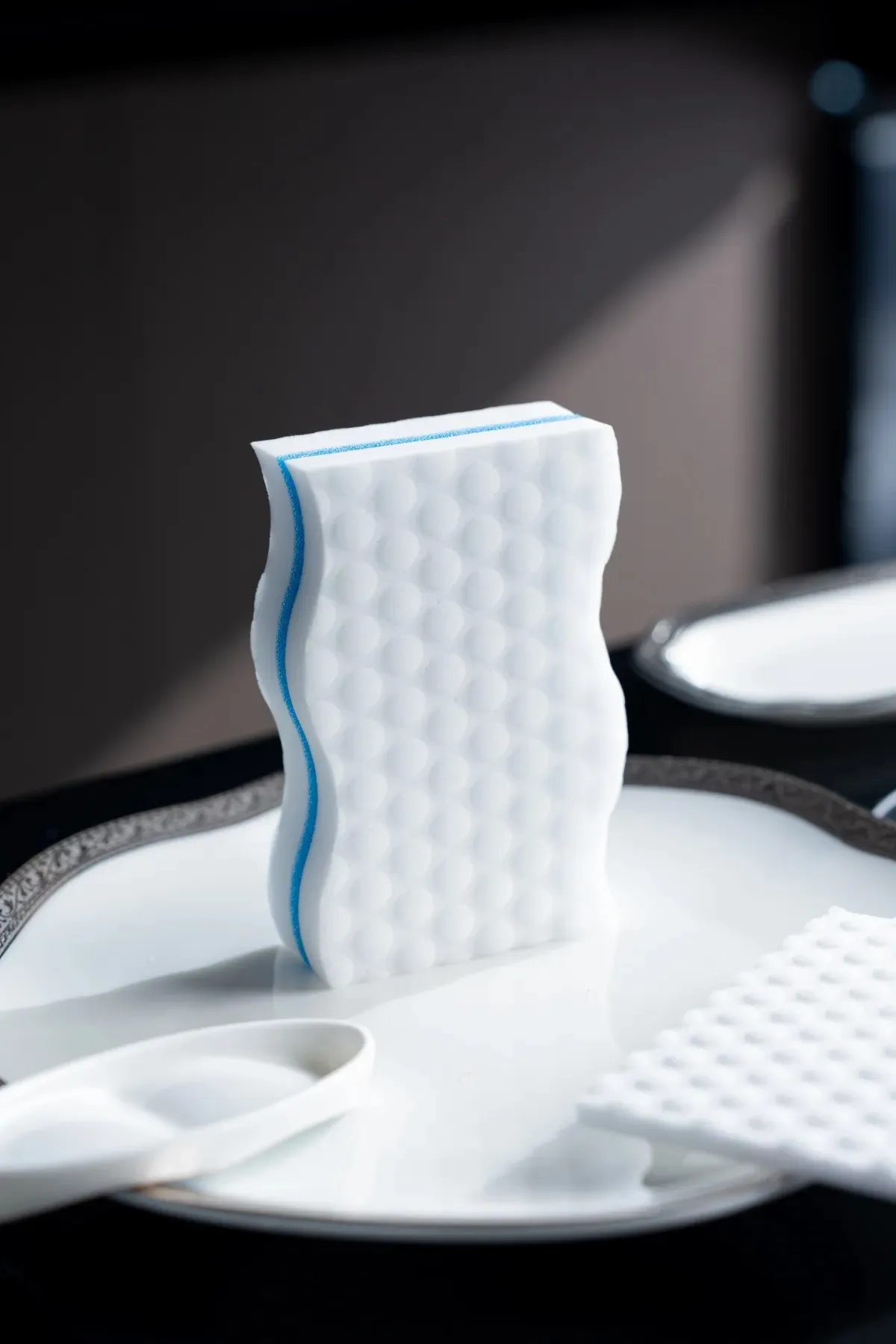

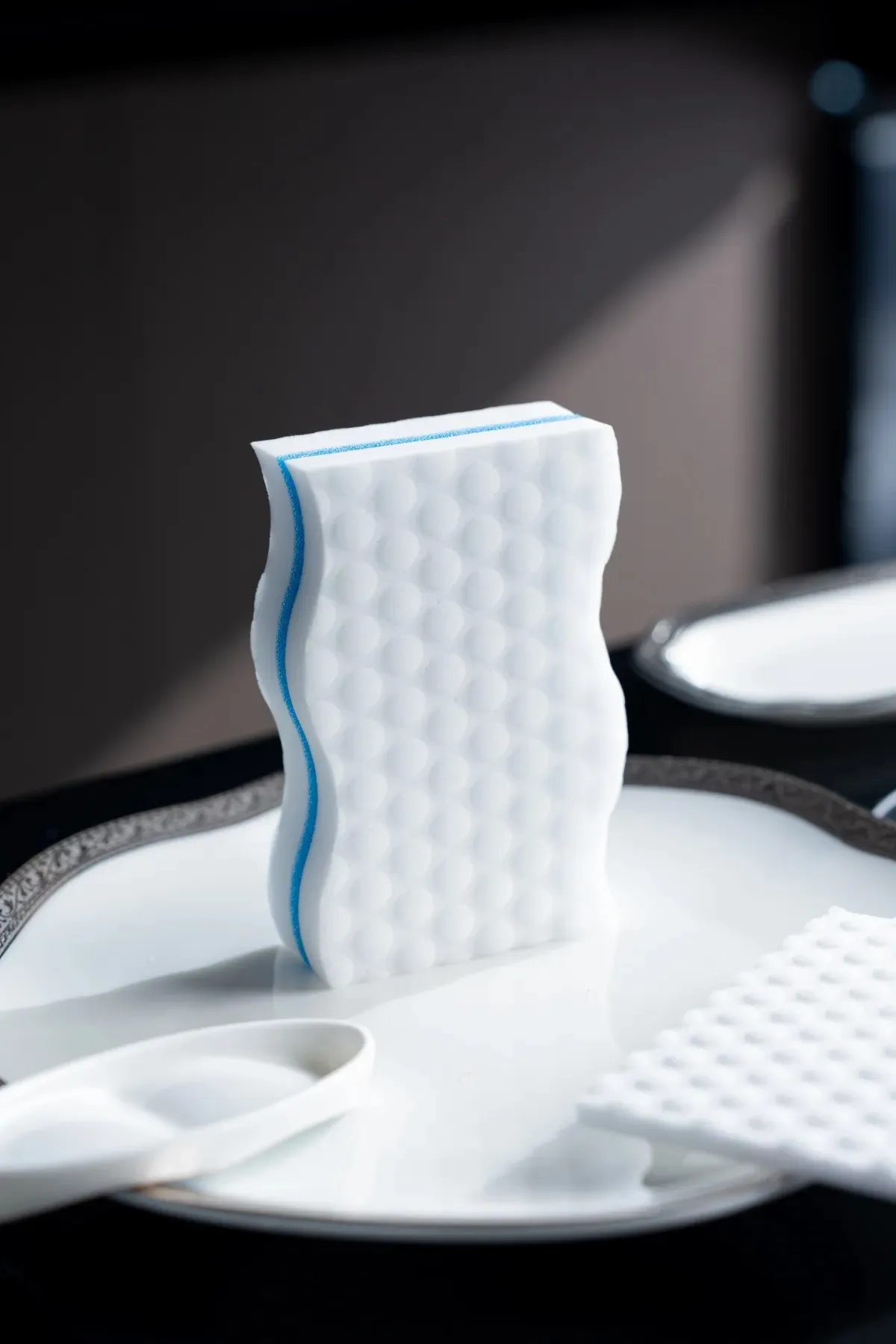

Design Innovation in Embossed Tri-Layer Variants

New ideas go past job to look. This boosts clean power and style mark.

Textured Surface Increases Frictional Contact

Stamped patterns raise touch on bumpy surfaces. No extra push needed. FoamTech sells stamped types like the Tri-Layer Embossed Melamine Sponge for set needs.

Improved Dirt Channeling During Cleaning

Groove designs move dirt from touch spots. This stops clogs. You get them only from FoamTech’s stamped line.

Aesthetic Differentiation and Brand Recognition

A clear texture lifts product draw for buyer jobs. It builds top spot feel.

Customization Capabilities from FoamTech

Custom fixes raise product work for set factory tasks.

Tailored Dimensions and Densities Based on Usage Needs

Cut-to-fit sizes aid hand or machine use. Densities change for job wants. FoamTech gives OEM services to match client specs.

Private Labeling Opportunities for Global Distributors

Mark options fit B2B or shop paths. Full design help comes too.

Technical Support and Quality Assurance Services

FoamTech conducts rigorous quality inspections on every batch of products through its in-house R&D team and ISO standards, while providing clients with direct professional guidance.

FAQ

Q1: What makes FoamTec’s Tri-Layer Melamine Sponge more durable than single-layer sponges?

A: It integrates melamine foam with a PU backing layer, enhancing tensile strength, resilience and shape stability. The engineered bonding process prevents tearing and deformation, outperforming single-layer sponges that lack structural support.

Q2: Are tri-layer melamine sponges safe for cleaning sensitive surfaces like car interiors?

A: Yes. German TÜV lab tests show their abrasion value on car paint is only 0.15 (far lower than 0.42 of traditional scrub pads), ensuring no scratches on delicate surfaces like electronics, car interiors and lab equipment.

Q3: Can tri-layer melamine sponges withstand harsh chemical environments?

A: Absolutely. The PU layer resists corrosion from pH1 - 14 acids and alkalis, while melamine foam maintains stability against solvents. They are suitable for cleaning equipment in chemical plants and industrial settings.

Tri-layer melamine sponges stand out as a better choice than old cleaning tools. They mix strong materials with smart design changes. This setup gives them good strength, heat resistance, and even scratch power. As a result, they work well in factory jobs and careful cleaning tasks. This piece looks at how material science boosts the use and money value of these sponges.

If you need tough cleaning tools from smart engineering and steady quality, check out FoamTech. It focuses on melamine sponge tech. The company has a full R&D and manufacturing background. Plus, it provides custom product making, OEM services, and solid shipping help.

Structural Advantages Boosting Mechanical Performance & Stability

FoamTech’s Tri-Layer Sandwich Melamine Sponge stands out for its innovative structural design. By integrating melamine foam with a PU backing, it achieves enhanced strength, flexibility and abrasive efficiency, while maintaining excellent thermal and chemical stability even under harsh cleaning conditions.

Structural Composition Enhances Mechanical Performance

The tri-layer sponge joins melamine foam with a polyurethane (PU) backing layer. This makes a tough structure. It boosts pull strength, bounce-back, and size steadiness under force. Melamine sponges have up to 99% open space. Each hole size stays between 5–20 microns. This helps cleaning work well. It also keeps the shape strong.

By mixing these materials, the sponge cuts down on rips and shape changes. Even in rough cleaning, it holds up. The Tri-Layer Sandwich Melamine Sponge fits for many uses. It avoids splitting or breaking. So, it gives better last power and sure work in hard spots.

Layer Integration Improves Abrasive Efficiency

A sponge's power to remove dirt relies on how it touches the surface and spreads push. The melamine layer works at tiny scale. It gives small scratch cleaning that picks up bits without harm. This material comes from melamine-formaldehyde resin. It goes through a special foam process. Its special 3D web shape has made a fresh cleaning way. It uses "physical rub instead of chemical break-down".

The PU layer helps spread force evenly over the sponge face. This boosts touch power. It also stops too much wear at one spot. The Tri-Layer Sandwich Melamine Sponge uses a smart join method. All layers team up. Thus, it keeps steady scratch work.

Thermal and Chemical Stability Under Harsh Conditions

In factory cleaning, sponges face heat and chemicals often. Melamine foam handles heat well. It keeps its strength even with rub heat. Its fire-stop power hits UL94 V-0 level. When in open fire, it makes a thick burned layer. No melt drops form.

The PU support layer fights off break from solvents and cleaning chemicals. Corrosion-resistant type: It takes pH1-14 acid and alkali spots. It fits for cleaning chemical plant gear. These traits keep the sponge steady in factory cleaning places.

Functional Benefits in Precision Cleaning Applications

Top sponges do more than clean. They fit soft surfaces, easy hold needs, and long use hopes.

Controlled Abrasion for Sensitive Surfaces

Many costly surfaces need no-scratch clean ways. Melamine foam's even hole size gives steady scratch without harm to covers or soft stuff. Tests from German TÜV lab show its rub number on car paint is just 0.15. That's way less than 0.42 for an old scrub pad. So, tri-layer sponges suit electronics, car insides, and lab care.

Enhanced Grip and Handling During Use

The PU backing layer adds easy-hold perks. It gives better hold in hand work. Users can push just right. It cuts tiredness in long jobs. FoamTech makes its sponges for pro use spots. This includes factory flows.

Extended Lifespan Reduces Replacement Frequency

Last power matters in money-tight jobs. Strong join between layers stops split in many uses. The thick foam fights squeeze. It keeps shape over cleaning rounds. High-quality items have density between 40–60kg/m³.

Comparative Advantage Over Single-Layer Sponges

Old melamine sponges may start strong. But they miss the build support for long use.

Structural Weaknesses of Traditional Melamine Sponges

One-layer setups break early from no support. Single-layer sponges lack strength boost. This leads to quick wear. They bend easy under long push or hard scrub jobs.

Performance Degradation in Single-Layer Designs

Without PU backing to spread force, one-layer melamine sponges get uneven wear. This cuts their life. It drops work over time. The tri-layer setup keeps steady power. It does this with better force handle and material stick.

Cost-Efficiency Through Longevity and Reliability

Start costs may run higher. Yet tri-layer sponges give better worth. They cut change needs. Less change means lower stuff use and work costs. Their strong build keeps clean power all through life.

Role of Material Interfaces in Multi-Layer Sponge Design

How layers touch sets how well tri-layer sponges work in real jobs.

Adhesion Techniques Between Layers Determine Durability

Last power ties right to layer stick. New join ways keep build together under push. FoamTech uses its own stick tech. This stops split in use.

Mechanical Synergy Between Layers Enhances Functionality

Each layer picks for its job. Melamine for scratch. PU for bend and strength. When built right, layers team up. This lifts full work past single parts.

Stress Distribution Across Layers Minimizes Wear Points

A many-layer build spreads push even. It skips spot harm that cuts life early. Good design gives longer use. Even in rough spots.

Application Versatility Across Industrial Sectors

Tri-layer melamine sponges shine in many fields. They adapt well and fight chemicals.

Suitability for Heavy-Duty Cleaning Tasks

They clean grease, rust, and paint bits well. No harm to base stuff. Uses go from kitchen shops to car clean.

Compatibility with Various Cleaning Agents

These sponges hold shape with alcohols, fat removers, or acid/base cleaners. They stand up to alcohols, soaps, fat removers in pro care.

Use Cases in Specialized Environments

In clean rooms or electronics lines, where bits must stay low, custom types work best. Antistatic type: Surface resistance 10^6-10^9Ω. It fits for cleaning electronic shops.

Design Innovation in Embossed Tri-Layer Variants

New ideas go past job to look. This boosts clean power and style mark.

Textured Surface Increases Frictional Contact

Stamped patterns raise touch on bumpy surfaces. No extra push needed. FoamTech sells stamped types like the Tri-Layer Embossed Melamine Sponge for set needs.

Improved Dirt Channeling During Cleaning

Groove designs move dirt from touch spots. This stops clogs. You get them only from FoamTech’s stamped line.

Aesthetic Differentiation and Brand Recognition

A clear texture lifts product draw for buyer jobs. It builds top spot feel.

Customization Capabilities from FoamTech

Custom fixes raise product work for set factory tasks.

Tailored Dimensions and Densities Based on Usage Needs

Cut-to-fit sizes aid hand or machine use. Densities change for job wants. FoamTech gives OEM services to match client specs.

Private Labeling Opportunities for Global Distributors

Mark options fit B2B or shop paths. Full design help comes too.

Technical Support and Quality Assurance Services

FoamTech conducts rigorous quality inspections on every batch of products through its in-house R&D team and ISO standards, while providing clients with direct professional guidance.

FAQ

Q1: What makes FoamTec’s Tri-Layer Melamine Sponge more durable than single-layer sponges?

A: It integrates melamine foam with a PU backing layer, enhancing tensile strength, resilience and shape stability. The engineered bonding process prevents tearing and deformation, outperforming single-layer sponges that lack structural support.

Q2: Are tri-layer melamine sponges safe for cleaning sensitive surfaces like car interiors?

A: Yes. German TÜV lab tests show their abrasion value on car paint is only 0.15 (far lower than 0.42 of traditional scrub pads), ensuring no scratches on delicate surfaces like electronics, car interiors and lab equipment.

Q3: Can tri-layer melamine sponges withstand harsh chemical environments?

A: Absolutely. The PU layer resists corrosion from pH1 - 14 acids and alkalis, while melamine foam maintains stability against solvents. They are suitable for cleaning equipment in chemical plants and industrial settings.