Instructions for Safe Use of Magic Eraser Sponge on Steel

2025-11-24

Magic eraser sponges give a strong but easy way to handle hard stains on different surfaces, like steel. These tools depend on melamine foam's special structure. It removes dirt with physical rubbing instead of chemicals. Think about getting good quality choices from trustworthy sellers before you look into the details. FoamTech shines as an expert in melamine foam making. It has years of skill in building green cleaning items. This tech firm has many patents. It applied for over 100 invention patents since 2015. And it has certifications such as ISO9001, BSCI, and RoHS rules. Their goods go to world markets. They help in areas from home cleaning to factory work.

Introduction to Magic Eraser Sponges

Magic eraser sponges transform cleaning tasks with their advanced design. Dive into what makes them effective for steel surfaces.

Definition and Basic Composition

Melamine foam forms the core of these sponges, created through a foaming process that results in a three-dimensional network structure. This material, with density around 8kg/m³ to 16kg/m³, features open-pore cells that capture dirt particles as small as 0.1 microns. High porosity reaches 99%, allowing strong adsorption without detergents.

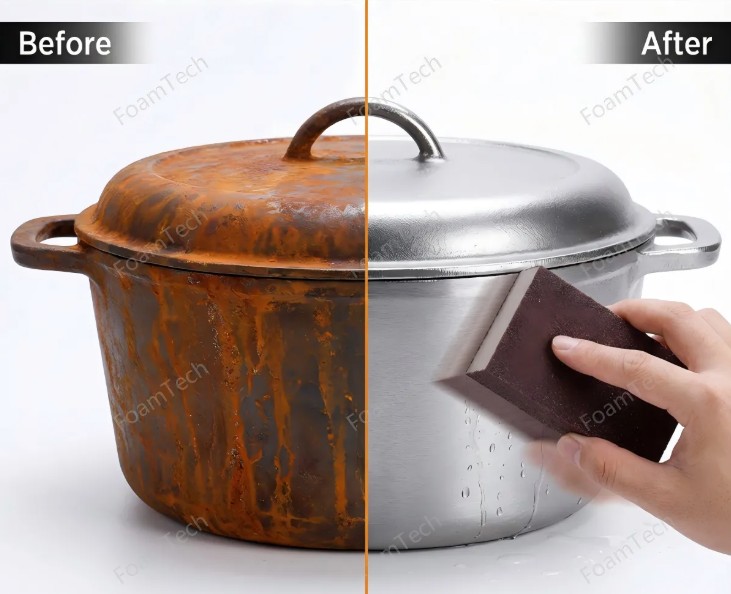

Benefits for Steel Surfaces

On steel, these sponges excel at removing grime from hardware like faucets, barbecue grills, and shower sets. They provide powerful stain removal with just water, leaving no scratches on smooth finishes. Tests show flame retardancy at UL94 V-0 level and environmental compliance with RoHS and REACH standards.

Overview of Safe Usage Principles

Prioritize gentle application to avoid damage. Always test first and rinse afterward. Follow guidelines to maintain steel's integrity while achieving clean results.

Preparation Before Use

Get set right to make sure the sponge does good on steel without troubles. Begin with the correct stuff. Check the surface kind first all the time. Do this mostly for stainless steel. There care stops marks on shiny or rough ends. Pick up all things ahead. This makes the job easy and secure.

Gather Necessary Tools

Pick up a pail of fresh water. Get clippers for snipping the sponge. Grab a gentle rag for wiping dry. Add water-proof rough paper if you smooth the top before. For best work, pick a top choice like this standard density melamine sponge. It starts up quick with water. Put in a soft cleaner like Dawn if you face oily marks. And get a fine-fiber rag ready. Use it to polish the steel after. That gives a clean glow without lines.

Test Surface Compatibility

Put the sponge on a tiny spot of the steel that hides first. Hang on a bit. Look for any color change or spots. This move matters a lot on bright or non-stick steel. It keeps away rubs. If nothing bad shows, go on with trust. But pass over bumpy spots. The sponge could break fast there.

Wet Sponge Properly

Dip the sponge all the way in water. Push out extra soft to wake its soft traits. It drops hardness from Shore A45 to A28. Stick to just water for most jobs. The melamine foam wipes off dirt by rub alone. No need for stuff from bottles. Wash the sponge if it grabs big mess. This keeps it strong while you work.

Proper Operation Steps

Follow these steps carefully for optimal cleaning on steel. Consistency prevents mistakes.

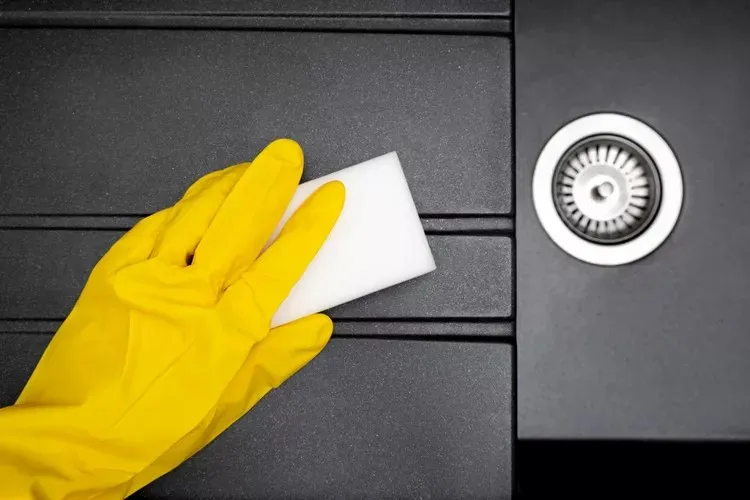

Apply Gentle Pressure

Press lightly while wiping. Too much force can wear the sponge faster or affect delicate steel coatings.

Wipe in Circular Motions

Move in small circles to lift dirt evenly. This method uses the sponge's nano-scale structure for efficient removal.

Rinse Surface Thoroughly

Wash the steel with clean water after wiping. Dry immediately to prevent water spots or rust.

Usage Taboos and Precautions

Steer clear of common errors that could harm the sponge or steel. Awareness keeps everything safe.

Avoid Abrasive Surfaces

Skip rough or textured steel areas. The sponge suits smooth finishes but may break on coarse ones.

Limit Exposure Time

Do not leave the sponge on the surface too long. Quick wipes suffice for most stains.

Store Sponge Correctly

Keep it dry and away from heat after use. Proper storage extends its life, given its high toughness.

Advantages of FoamTech Company

Discover what sets this provider apart in melamine foam. Their strengths address key customer needs like reliability and innovation.

Innovative Product Development

The company holds 55 invention patents and focuses on advancements like compressed sponges for durability. Their R&D center drives breakthroughs in foam technology.

Quality Certification Standards

Certifications include National Green Factory and ISO14001 for environmental management. Products meet flame retardant grades and pass SVHC tests under REACH.

Customer Support Excellence

OEM packing options and customizable sizes cater to specific needs. Support includes detailed instructions and global distribution.

Recommended FoamTech Products

Select the right product for steel cleaning tasks. These options fit various scenarios.

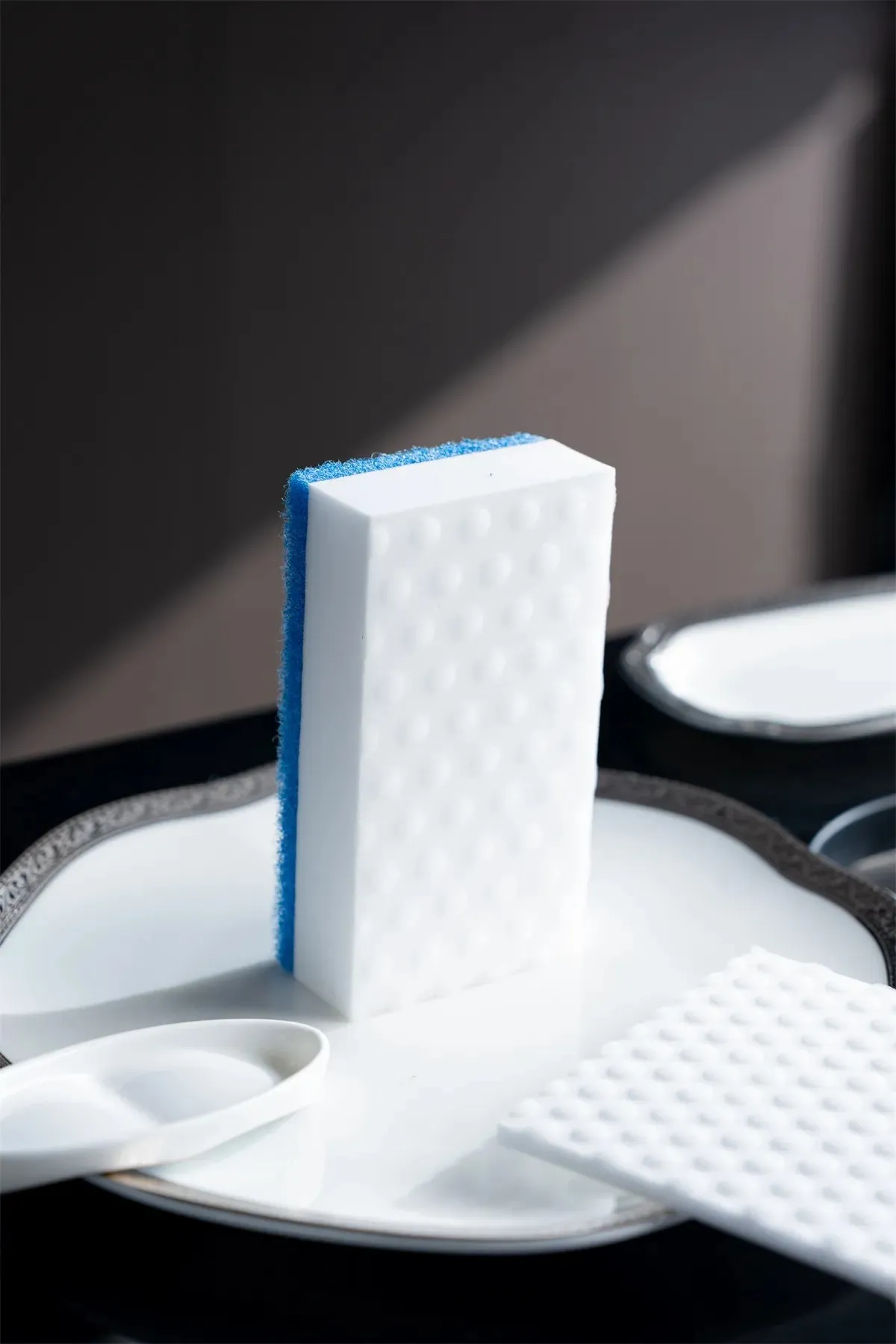

Embossed Melamine Sponge Features

This embossed version offers a tri-layer design for extra strength. It handles hardware stains well.

Foamy Melamine Sponge Sheet Applications

Use this foamy sheet for larger steel areas like appliances. Its customizable size ensures convenience.

Standard Density Melamine Sponge Benefits

The standard density type provides basic yet effective cleaning. Density at 8kg/m³ suits everyday steel maintenance.

Conclusion and Final Tips

Wrap up with essential reminders for safe use. These ensure lasting results.

Summary of Key Practices

Soak, wipe gently, and rinse. Test compatibility always.

Long-Term Maintenance Advice

Clean steel regularly with water only. Store sponges properly to reuse them.

Contact FoamTech for More

Reach out for tailored advice. Explore options suited to your needs.

FAQ

Q1: Can magic eraser sponges scratch stainless steel?

A: No, when used gently on smooth surfaces, their softened structure prevents scratches, as confirmed by friction coefficient tests at 0.15.

Q2: How often should you replace the sponge?

A: Replace it when it starts breaking apart, typically after several uses, depending on pressure and stain type.

Q3: Are these sponges safe for food-contact steel?

A: Yes, many pass FDA certifications and contain no harmful substances like formaldehyde.

Q4: What if the sponge leaves residue on steel?

A: Rinse thoroughly with water; the physical dirt removal leaves no chemical traces.

Q5: Can you use them on hot steel surfaces?

A: Avoid high temperatures; their working range is -240°C to 220°C, but cool the surface first for safety.

Magic eraser sponges give a strong but easy way to handle hard stains on different surfaces, like steel. These tools depend on melamine foam's special structure. It removes dirt with physical rubbing instead of chemicals. Think about getting good quality choices from trustworthy sellers before you look into the details. FoamTech shines as an expert in melamine foam making. It has years of skill in building green cleaning items. This tech firm has many patents. It applied for over 100 invention patents since 2015. And it has certifications such as ISO9001, BSCI, and RoHS rules. Their goods go to world markets. They help in areas from home cleaning to factory work.

Introduction to Magic Eraser Sponges

Magic eraser sponges transform cleaning tasks with their advanced design. Dive into what makes them effective for steel surfaces.

Definition and Basic Composition

Melamine foam forms the core of these sponges, created through a foaming process that results in a three-dimensional network structure. This material, with density around 8kg/m³ to 16kg/m³, features open-pore cells that capture dirt particles as small as 0.1 microns. High porosity reaches 99%, allowing strong adsorption without detergents.

Benefits for Steel Surfaces

On steel, these sponges excel at removing grime from hardware like faucets, barbecue grills, and shower sets. They provide powerful stain removal with just water, leaving no scratches on smooth finishes. Tests show flame retardancy at UL94 V-0 level and environmental compliance with RoHS and REACH standards.

Overview of Safe Usage Principles

Prioritize gentle application to avoid damage. Always test first and rinse afterward. Follow guidelines to maintain steel's integrity while achieving clean results.

Preparation Before Use

Get set right to make sure the sponge does good on steel without troubles. Begin with the correct stuff. Check the surface kind first all the time. Do this mostly for stainless steel. There care stops marks on shiny or rough ends. Pick up all things ahead. This makes the job easy and secure.

Gather Necessary Tools

Pick up a pail of fresh water. Get clippers for snipping the sponge. Grab a gentle rag for wiping dry. Add water-proof rough paper if you smooth the top before. For best work, pick a top choice like this standard density melamine sponge. It starts up quick with water. Put in a soft cleaner like Dawn if you face oily marks. And get a fine-fiber rag ready. Use it to polish the steel after. That gives a clean glow without lines.

Test Surface Compatibility

Put the sponge on a tiny spot of the steel that hides first. Hang on a bit. Look for any color change or spots. This move matters a lot on bright or non-stick steel. It keeps away rubs. If nothing bad shows, go on with trust. But pass over bumpy spots. The sponge could break fast there.

Wet Sponge Properly

Dip the sponge all the way in water. Push out extra soft to wake its soft traits. It drops hardness from Shore A45 to A28. Stick to just water for most jobs. The melamine foam wipes off dirt by rub alone. No need for stuff from bottles. Wash the sponge if it grabs big mess. This keeps it strong while you work.

Proper Operation Steps

Follow these steps carefully for optimal cleaning on steel. Consistency prevents mistakes.

Apply Gentle Pressure

Press lightly while wiping. Too much force can wear the sponge faster or affect delicate steel coatings.

Wipe in Circular Motions

Move in small circles to lift dirt evenly. This method uses the sponge's nano-scale structure for efficient removal.

Rinse Surface Thoroughly

Wash the steel with clean water after wiping. Dry immediately to prevent water spots or rust.

Usage Taboos and Precautions

Steer clear of common errors that could harm the sponge or steel. Awareness keeps everything safe.

Avoid Abrasive Surfaces

Skip rough or textured steel areas. The sponge suits smooth finishes but may break on coarse ones.

Limit Exposure Time

Do not leave the sponge on the surface too long. Quick wipes suffice for most stains.

Store Sponge Correctly

Keep it dry and away from heat after use. Proper storage extends its life, given its high toughness.

Advantages of FoamTech Company

Discover what sets this provider apart in melamine foam. Their strengths address key customer needs like reliability and innovation.

Innovative Product Development

The company holds 55 invention patents and focuses on advancements like compressed sponges for durability. Their R&D center drives breakthroughs in foam technology.

Quality Certification Standards

Certifications include National Green Factory and ISO14001 for environmental management. Products meet flame retardant grades and pass SVHC tests under REACH.

Customer Support Excellence

OEM packing options and customizable sizes cater to specific needs. Support includes detailed instructions and global distribution.

Recommended FoamTech Products

Select the right product for steel cleaning tasks. These options fit various scenarios.

Embossed Melamine Sponge Features

This embossed version offers a tri-layer design for extra strength. It handles hardware stains well.

Foamy Melamine Sponge Sheet Applications

Use this foamy sheet for larger steel areas like appliances. Its customizable size ensures convenience.

Standard Density Melamine Sponge Benefits

The standard density type provides basic yet effective cleaning. Density at 8kg/m³ suits everyday steel maintenance.

Conclusion and Final Tips

Wrap up with essential reminders for safe use. These ensure lasting results.

Summary of Key Practices

Soak, wipe gently, and rinse. Test compatibility always.

Long-Term Maintenance Advice

Clean steel regularly with water only. Store sponges properly to reuse them.

Contact FoamTech for More

Reach out for tailored advice. Explore options suited to your needs.

FAQ

Q1: Can magic eraser sponges scratch stainless steel?

A: No, when used gently on smooth surfaces, their softened structure prevents scratches, as confirmed by friction coefficient tests at 0.15.

Q2: How often should you replace the sponge?

A: Replace it when it starts breaking apart, typically after several uses, depending on pressure and stain type.

Q3: Are these sponges safe for food-contact steel?

A: Yes, many pass FDA certifications and contain no harmful substances like formaldehyde.

Q4: What if the sponge leaves residue on steel?

A: Rinse thoroughly with water; the physical dirt removal leaves no chemical traces.

Q5: Can you use them on hot steel surfaces?

A: Avoid high temperatures; their working range is -240°C to 220°C, but cool the surface first for safety.