The Ultimate Comparison of S-shape and Hot-pressed Cleaning Sponges

2026-02-09

The worldwide cleaning sector moves toward efficient, chemical-free options. Businesses seek tools that offer good value along with strong performance, and nano-melamine technology serves as the key standard. Understanding the main technical differences among sponge types helps deliver optimal value to clients and users.

For more than ten years, FoamTech has built a strong position as a global leader and Melamine Foam Expert. From modern facilities, this advanced company focuses on research, development, and large-scale production of quality melamine foam. In fields like aviation, rail transit, or retail, partners gain from a supplier with many patents and certifications such as BSCI and ISO 9001. Their comprehensive services cover raw material supply to full custom OEM/ODM options, so inventory aligns with global quality and safety standards.

Definition and Core Advantages of Each Variant

Selecting the proper cleaning tool begins with knowing the foam technology involved. Although all melamine items rely on physical adsorption to remove dirt, the production method sets the performance boundaries for each sponge.

Versatile S-shape Magic Cleaning Sponges

The Magic Cleaning Sponge includes a dense nano-melamine build, often in a three-layer composite setup. Its S-curve design matches hand shapes for improved grip, and the nano-capillary features work as tiny scrubbers to remove grease and marks with just water.

High-density Hot-pressed Melamine Sponges

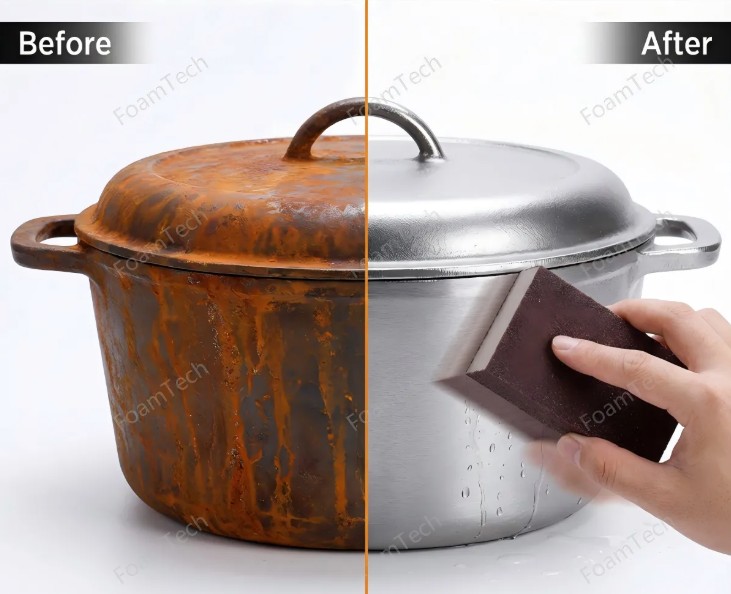

The Hot-pressed sponge goes through a thermal compression process. This method shrinks the foam volume while keeping the open-cell resin form, which creates a much stronger material. Such sponges suit intense scrubbing tasks where regular types might break or wear out quickly.

Shared Benefits of Nano Materials

Both types prove eco-friendly and antibacterial, so they avoid toxic cleaners. They follow strict global rules like REACH and ROHS, which makes them safe for food areas and home settings. The physical cleaning action leaves no chemical traces after use.

Structural Differences and Physical Composition

A sponge's physical strength decides its response to pressure. Variations in density and surface shape set the friction and feel during application.

Ergonomic Multi-layer Design

The S-shape type usually uses a layered build where melamine foam attaches to a PU or PE middle layer. This setup keeps the sponge from getting too soft as it ages, and the curve shape lets users apply steady pressure over the surface, which cuts down on hand strain in extended sessions.

Compressed Density and Firmness

Standard melamine foam density ranges from $8kg/m^3$ to $16kg/m^3$, but hot-pressed versions achieve higher levels via compression. This boost in density gives a solid pad-like feel, and the material resists easy squeezing, so users can focus force on tough spots with accuracy.

Surface Textures for Friction

Surface pattern affects cleaning power greatly. S-shape models often have raised diamond designs that grab and remove debris, whereas hot-pressed ones feature grid patterns or even, high-grip surfaces. These elements boost contact between the nano-foam and stains for better results.

Durability and Longevity in Commercial Use

In professional services and heavy use, a sponge's service life matters a lot. The gap between regular dense foam and hot-pressed foam shows clearest in strength tests.

Anti-tearing and Flexibility Limits

Common magic erasers often break or shed bits in action. Hot-pressing boosts the foam's pull strength, so twisting or squeezing causes far less damage than in untreated forms.

Lifespan Under Heavy Scrubbing

The hot-pressed type packs more cleaning material into less space, which slows wear. It holds form well on rough areas like grout or bumpy plastic, and this endurance means fewer changes and lower costs per use for operations.

Water Retention and Absorption Rates

The open-cell design absorbs water up to 750% to 2000% of its weight. Right moisture activates the nano-scrubbers, and the dense build releases water slowly for steady cleaning without frequent re-wetting.

Ideal Application Scenarios

Pairing sponge type to tasks boosts satisfaction and avoids surface harm. Various settings need specific abrasion and bend levels.

Domestic and Hospitality Excellence

The S-shape composite suits home care and hotel work best. Its gentle feel and hand-fit grip work well on items like ceramic sinks, glass doors, and steel appliances, while the layered look adds polish to sales packages.

Industrial and Heavy Duty Cleaning

For car care, machine upkeep, or floor mark removal in busy spots, the hot-pressed sponge excels. It manages strong rubs on metal and hard plastics without crumbling, and its slim, stiff shape fits into tight spaces easily.

Precision Cleaning for Specialty Goods

Cleaning detailed pieces like sneaker soles, leather seats, or device shells calls for hot-pressed firmness. This allows exact targeting of stains like ink or crayon, so nearby areas stay safe.

Why Choose FoamTech as Your Global Supplier

A steady supply chain supports market edge. Working with a focused maker offers tech help and quality checks for worldwide sales.

Manufacturing Expertise and Facilities

FoamTech draws on years of family-run leadership. Access comes to modern lines for melamine processing to packaging, with quick 12-hour replies to meet buying needs.

Comprehensive OEM and ODM Services

Customization stands as a key FoamTech team skill. Requests for set densities, shapes, or colors help brand standout, and free samples confirm fit before large orders.

Compliance and International Certifications

Imports proceed safely with full certifications. IATF 16949, BSCI, and UL standards ensure top social and quality practices, leading to full positive reviews from global partners.

FAQ

Q1: Do these sponges require any chemical cleaners to work effectively?

A: No, both the S-shape and hot-pressed sponges use physical nano-technology to lift dirt and only require water for activation.

Q2: Can the hot-pressed sponge be used on delicate or painted surfaces?

A: Because of its high density and friction, you should test it on an inconspicuous area first to ensure it does not dull the finish of sensitive surfaces.

Q3: What is the main advantage of the S-shape design for retail customers?

A: The ergonomic S-shape fits the hand comfortably and the multi-layer structure provides a familiar "sponge-like" feel that is easier for general consumers to use.

Q4: Are these melamine sponges biodegradable or eco-friendly?

A: They are eco-friendly as they reduce the need for chemical detergents; however, they should be disposed of according to local plastic waste regulations.

Q5: How can I request a quote for bulk wholesale or custom branding?

A: You can reach out directly via the contact page to discuss your specific volume requirements and customization needs with a specialist.

The worldwide cleaning sector moves toward efficient, chemical-free options. Businesses seek tools that offer good value along with strong performance, and nano-melamine technology serves as the key standard. Understanding the main technical differences among sponge types helps deliver optimal value to clients and users.

For more than ten years, FoamTech has built a strong position as a global leader and Melamine Foam Expert. From modern facilities, this advanced company focuses on research, development, and large-scale production of quality melamine foam. In fields like aviation, rail transit, or retail, partners gain from a supplier with many patents and certifications such as BSCI and ISO 9001. Their comprehensive services cover raw material supply to full custom OEM/ODM options, so inventory aligns with global quality and safety standards.

Definition and Core Advantages of Each Variant

Selecting the proper cleaning tool begins with knowing the foam technology involved. Although all melamine items rely on physical adsorption to remove dirt, the production method sets the performance boundaries for each sponge.

Versatile S-shape Magic Cleaning Sponges

The Magic Cleaning Sponge includes a dense nano-melamine build, often in a three-layer composite setup. Its S-curve design matches hand shapes for improved grip, and the nano-capillary features work as tiny scrubbers to remove grease and marks with just water.

High-density Hot-pressed Melamine Sponges

The Hot-pressed sponge goes through a thermal compression process. This method shrinks the foam volume while keeping the open-cell resin form, which creates a much stronger material. Such sponges suit intense scrubbing tasks where regular types might break or wear out quickly.

Shared Benefits of Nano Materials

Both types prove eco-friendly and antibacterial, so they avoid toxic cleaners. They follow strict global rules like REACH and ROHS, which makes them safe for food areas and home settings. The physical cleaning action leaves no chemical traces after use.

Structural Differences and Physical Composition

A sponge's physical strength decides its response to pressure. Variations in density and surface shape set the friction and feel during application.

Ergonomic Multi-layer Design

The S-shape type usually uses a layered build where melamine foam attaches to a PU or PE middle layer. This setup keeps the sponge from getting too soft as it ages, and the curve shape lets users apply steady pressure over the surface, which cuts down on hand strain in extended sessions.

Compressed Density and Firmness

Standard melamine foam density ranges from $8kg/m^3$ to $16kg/m^3$, but hot-pressed versions achieve higher levels via compression. This boost in density gives a solid pad-like feel, and the material resists easy squeezing, so users can focus force on tough spots with accuracy.

Surface Textures for Friction

Surface pattern affects cleaning power greatly. S-shape models often have raised diamond designs that grab and remove debris, whereas hot-pressed ones feature grid patterns or even, high-grip surfaces. These elements boost contact between the nano-foam and stains for better results.

Durability and Longevity in Commercial Use

In professional services and heavy use, a sponge's service life matters a lot. The gap between regular dense foam and hot-pressed foam shows clearest in strength tests.

Anti-tearing and Flexibility Limits

Common magic erasers often break or shed bits in action. Hot-pressing boosts the foam's pull strength, so twisting or squeezing causes far less damage than in untreated forms.

Lifespan Under Heavy Scrubbing

The hot-pressed type packs more cleaning material into less space, which slows wear. It holds form well on rough areas like grout or bumpy plastic, and this endurance means fewer changes and lower costs per use for operations.

Water Retention and Absorption Rates

The open-cell design absorbs water up to 750% to 2000% of its weight. Right moisture activates the nano-scrubbers, and the dense build releases water slowly for steady cleaning without frequent re-wetting.

Ideal Application Scenarios

Pairing sponge type to tasks boosts satisfaction and avoids surface harm. Various settings need specific abrasion and bend levels.

Domestic and Hospitality Excellence

The S-shape composite suits home care and hotel work best. Its gentle feel and hand-fit grip work well on items like ceramic sinks, glass doors, and steel appliances, while the layered look adds polish to sales packages.

Industrial and Heavy Duty Cleaning

For car care, machine upkeep, or floor mark removal in busy spots, the hot-pressed sponge excels. It manages strong rubs on metal and hard plastics without crumbling, and its slim, stiff shape fits into tight spaces easily.

Precision Cleaning for Specialty Goods

Cleaning detailed pieces like sneaker soles, leather seats, or device shells calls for hot-pressed firmness. This allows exact targeting of stains like ink or crayon, so nearby areas stay safe.

Why Choose FoamTech as Your Global Supplier

A steady supply chain supports market edge. Working with a focused maker offers tech help and quality checks for worldwide sales.

Manufacturing Expertise and Facilities

FoamTech draws on years of family-run leadership. Access comes to modern lines for melamine processing to packaging, with quick 12-hour replies to meet buying needs.

Comprehensive OEM and ODM Services

Customization stands as a key FoamTech team skill. Requests for set densities, shapes, or colors help brand standout, and free samples confirm fit before large orders.

Compliance and International Certifications

Imports proceed safely with full certifications. IATF 16949, BSCI, and UL standards ensure top social and quality practices, leading to full positive reviews from global partners.

FAQ

Q1: Do these sponges require any chemical cleaners to work effectively?

A: No, both the S-shape and hot-pressed sponges use physical nano-technology to lift dirt and only require water for activation.

Q2: Can the hot-pressed sponge be used on delicate or painted surfaces?

A: Because of its high density and friction, you should test it on an inconspicuous area first to ensure it does not dull the finish of sensitive surfaces.

Q3: What is the main advantage of the S-shape design for retail customers?

A: The ergonomic S-shape fits the hand comfortably and the multi-layer structure provides a familiar "sponge-like" feel that is easier for general consumers to use.

Q4: Are these melamine sponges biodegradable or eco-friendly?

A: They are eco-friendly as they reduce the need for chemical detergents; however, they should be disposed of according to local plastic waste regulations.

Q5: How can I request a quote for bulk wholesale or custom branding?

A: You can reach out directly via the contact page to discuss your specific volume requirements and customization needs with a specialist.

Prev: No data