Should Magic Eraser Be Used Wet or Dry for Maximum Abrasive Efficiency

2025-10-27

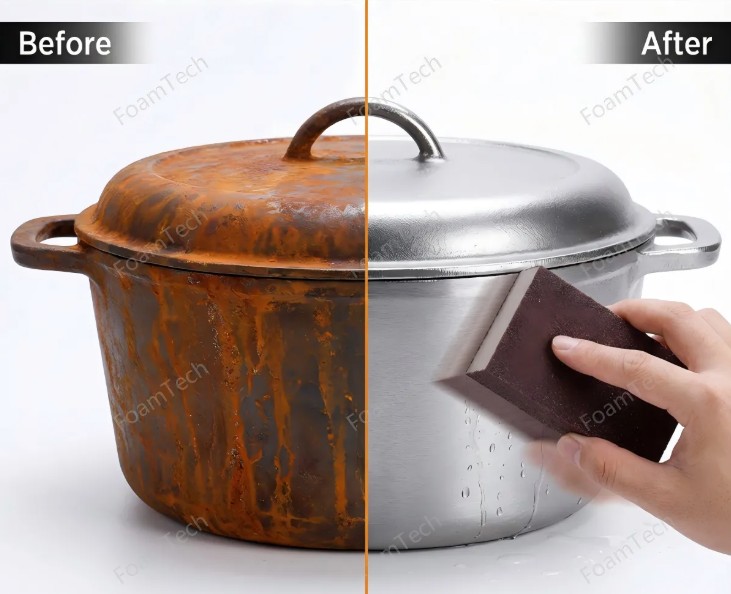

The choice between wet and dry application of a magic eraser when cleaning ceramic bisqueware or industrial surfaces determines the final outcome of your cleaning process. The melamine foam cleaning tools seem basic yet their microscopic structure and environmental responses remain complex. The following article explains the scientific principles of magic erasers and provides guidance on their proper usage with water or without it. The FoamTech company provides professional-grade melamine sponges with advanced features that include high-density materials and embossed textures and multi-layered designs for both home and industrial cleaning needs. The products from FoamTech work for physical dirt removal without chemicals and users can reuse them after washing them with water.

What Is the Science Behind Magic Eraser's Cleaning Power?

The effectiveness of Magic erasers stems from their composition of melamine foam which operates as tiny microscopic sandpaper particles. The effectiveness of Magic erasers depends on more than their surface appearance because their cells contain microscopic sandpaper-like properties.

Melamine Foam Structure and Abrasive Properties

The manufacturing process of melamine foam involves vacuum foaming which produces 98% uniform pores. The material has a dense open-cell structure that functions as micro-abrasives when used. The rigid polymer network in melamine foam works as a gentle abrasive that removes particles from surfaces while preserving the integrity of tile and glass materials.

Microstructure Interaction with Dirt and Stains

The pores function as minuscule traps which capture debris particles. The foam structure enables it to remove particles that are trapped in textured areas or wedged in small spaces. The foam removes unwanted color while producing a clean and precise finish for my work. The physical action of magic erasers enables them to clean surfaces without requiring any detergents or dangerous chemicals.

Role of Water in Activating Cleaning Potential

The sponge becomes slightly softer when exposed to water because water reduces surface friction and enables capillary action to pull away dirt particles from the foam cells. Soak the sponge with water before you squeeze out the water and then use it for cleaning and finally rinse and reuse it. The liquid in the sponge keeps particles floating in the solution which makes them simpler to clean away instead of creating surface smudges.

How Does Using Magic Eraser Dry Affect Performance?

The method of using a magic eraser dry does not constitute an error but it alters the product's operational characteristics. The method might work perfectly for your specific cleaning needs. You should evaluate the disadvantages of skipping the soaking process before making your decision.

Increased Friction and Surface Resistance

Dry melamine foam contains a rigid polymer matrix which produces higher surface resistance. The increased abrasive force comes with a higher danger of damaging sensitive surfaces and painted areas.

Faster Wear and Tear of the Sponge Material

The absence of water as a lubricant causes materials to deteriorate at an increased rate because of rising friction. The sponge deteriorates more quickly when used dry because it encounters higher friction on unglazed ceramic and concrete surfaces.

Limited Dirt Absorption Without Moisture

Dry foam fails to perform capillary action which prevents it from drawing dirt particles into its pores. The foam fails to remove dirt effectively because it tends to spread dirt particles throughout the surface when cleaning oily substances or sticky messes.

What Are the Benefits of Using Magic Eraser Wet?

The addition of water enables smooth wiping while simultaneously activating vital cellular processes which enhance both operational efficiency and product durability.

Enhanced Glide and Reduced Surface Damage

The drag resistance decreases when you use moisture for wiping which helps protect surfaces with sensitive finishes including polished wood and painted drywall from accidental scratches. The extended cleaning process becomes less strenuous because of moisture which is crucial for handling big cleaning tasks.

Improved Dirt Suspension and Removal Efficiency

Water acts as a suspension agent for particles that abrasion has released because it prevents them from settling back onto cleaned surfaces. Clean with water alone; Soaked in water and reuse; Powerful cleaning. The cleaning process produces better results with less effort because of the reduced number of passes needed for each area.

Activation of Capillary Action Within Foam Cells

The pores function as tiny suction devices which draw debris into them through capillary action because of their uniform structure that results from the manufacturing Foaming process. Vacuum foaming technology enables the production of pores with 98% uniformity.

How Do FoamTech Products Perform Under Wet and Dry Conditions?

The FoamTech company produces melamine sponges which serve specific functions based on their performance characteristics under various moisture conditions.

Foamy Melamine Sponge Sheet for Versatile Cleaning Tasks

The Foamy Melamine Sponge Sheet functions as a multi-purpose cleaning tool because it has a suitable density level that makes it work on kitchen counters and office desks. The sponge works effectively for fast cleaning when dry and provides thorough cleaning when used with water.

Embossed Melamine Sponge for Enhanced Surface Contact

The Embossed Melamine Sponge has textured surfaces which provide more contact points and lower cleaning pressure requirements because it needs to reach all areas of uneven surfaces like textured tiles and stucco walls.

Tri-Layer “Sandwich” Embossed Melamine Sponge for Durability and Control

The Tri-Layer “Sandwich” Embossed Melamine Sponge features three distinct layers which provide stability during rough scrubbing operations while its abrasive top sheet helps users maintain control through better grip even when the sponge becomes wet.

What Role Does Sponge Design Play in Abrasive Efficiency?

The design of melamine sponges determines their performance levels more than users understand because different designs function differently in different situations.

Effect of Embossed Texture on Friction Management

The embossed patterns on the surface of the sponge work to break up surface tension because they direct force pressure toward the raised ridges instead of distributing it uniformly across flat areas. The design pattern minimizes drag resistance while it helps to penetrate into the grooves where dirt accumulates.

Influence of Multi-Layer Structure on Pressure Distribution

The Multi-layer sponge design provides uniform force distribution across its surface area which helps users avoid fatigue during extended scrubbing tasks. The Tri-Layer “Sandwich” Embossed Melamine Sponge.

Impact of Density and Thickness on Water Retention and Release

Higher-density foams maintain water absorption for extended periods while preventing excessive dripping which makes them suitable for vertical installations such as shower walls and provide sufficient cushioning against pressure surges that protect sensitive finishes. High-quality products maintain a density range between 40-60kg/m³.

FAQ

Q1: What makes my magic eraser deteriorate at a fast rate?

A: The dry usage of the Magic Eraser produces excessive friction which shortens its lifespan because it operates better when used with damp conditions that provide smooth gliding.

Q2: What steps can I take to make my sponge last longer?

A: The sponge will last longer if you dry it immediately after cleaning and soak it in vinegar once a month and stay away from strong oxidizing agents.

Q3: What makes embossed designs unique?

A: The design pattern creates better contact efficiency through its raised elements which direct pressure and minimize drag when wiping.

The choice between wet and dry application of a magic eraser when cleaning ceramic bisqueware or industrial surfaces determines the final outcome of your cleaning process. The melamine foam cleaning tools seem basic yet their microscopic structure and environmental responses remain complex. The following article explains the scientific principles of magic erasers and provides guidance on their proper usage with water or without it. The FoamTech company provides professional-grade melamine sponges with advanced features that include high-density materials and embossed textures and multi-layered designs for both home and industrial cleaning needs. The products from FoamTech work for physical dirt removal without chemicals and users can reuse them after washing them with water.

What Is the Science Behind Magic Eraser's Cleaning Power?

The effectiveness of Magic erasers stems from their composition of melamine foam which operates as tiny microscopic sandpaper particles. The effectiveness of Magic erasers depends on more than their surface appearance because their cells contain microscopic sandpaper-like properties.

Melamine Foam Structure and Abrasive Properties

The manufacturing process of melamine foam involves vacuum foaming which produces 98% uniform pores. The material has a dense open-cell structure that functions as micro-abrasives when used. The rigid polymer network in melamine foam works as a gentle abrasive that removes particles from surfaces while preserving the integrity of tile and glass materials.

Microstructure Interaction with Dirt and Stains

The pores function as minuscule traps which capture debris particles. The foam structure enables it to remove particles that are trapped in textured areas or wedged in small spaces. The foam removes unwanted color while producing a clean and precise finish for my work. The physical action of magic erasers enables them to clean surfaces without requiring any detergents or dangerous chemicals.

Role of Water in Activating Cleaning Potential

The sponge becomes slightly softer when exposed to water because water reduces surface friction and enables capillary action to pull away dirt particles from the foam cells. Soak the sponge with water before you squeeze out the water and then use it for cleaning and finally rinse and reuse it. The liquid in the sponge keeps particles floating in the solution which makes them simpler to clean away instead of creating surface smudges.

How Does Using Magic Eraser Dry Affect Performance?

The method of using a magic eraser dry does not constitute an error but it alters the product's operational characteristics. The method might work perfectly for your specific cleaning needs. You should evaluate the disadvantages of skipping the soaking process before making your decision.

Increased Friction and Surface Resistance

Dry melamine foam contains a rigid polymer matrix which produces higher surface resistance. The increased abrasive force comes with a higher danger of damaging sensitive surfaces and painted areas.

Faster Wear and Tear of the Sponge Material

The absence of water as a lubricant causes materials to deteriorate at an increased rate because of rising friction. The sponge deteriorates more quickly when used dry because it encounters higher friction on unglazed ceramic and concrete surfaces.

Limited Dirt Absorption Without Moisture

Dry foam fails to perform capillary action which prevents it from drawing dirt particles into its pores. The foam fails to remove dirt effectively because it tends to spread dirt particles throughout the surface when cleaning oily substances or sticky messes.

What Are the Benefits of Using Magic Eraser Wet?

The addition of water enables smooth wiping while simultaneously activating vital cellular processes which enhance both operational efficiency and product durability.

Enhanced Glide and Reduced Surface Damage

The drag resistance decreases when you use moisture for wiping which helps protect surfaces with sensitive finishes including polished wood and painted drywall from accidental scratches. The extended cleaning process becomes less strenuous because of moisture which is crucial for handling big cleaning tasks.

Improved Dirt Suspension and Removal Efficiency

Water acts as a suspension agent for particles that abrasion has released because it prevents them from settling back onto cleaned surfaces. Clean with water alone; Soaked in water and reuse; Powerful cleaning. The cleaning process produces better results with less effort because of the reduced number of passes needed for each area.

Activation of Capillary Action Within Foam Cells

The pores function as tiny suction devices which draw debris into them through capillary action because of their uniform structure that results from the manufacturing Foaming process. Vacuum foaming technology enables the production of pores with 98% uniformity.

How Do FoamTech Products Perform Under Wet and Dry Conditions?

The FoamTech company produces melamine sponges which serve specific functions based on their performance characteristics under various moisture conditions.

Foamy Melamine Sponge Sheet for Versatile Cleaning Tasks

The Foamy Melamine Sponge Sheet functions as a multi-purpose cleaning tool because it has a suitable density level that makes it work on kitchen counters and office desks. The sponge works effectively for fast cleaning when dry and provides thorough cleaning when used with water.

Embossed Melamine Sponge for Enhanced Surface Contact

The Embossed Melamine Sponge has textured surfaces which provide more contact points and lower cleaning pressure requirements because it needs to reach all areas of uneven surfaces like textured tiles and stucco walls.

Tri-Layer “Sandwich” Embossed Melamine Sponge for Durability and Control

The Tri-Layer “Sandwich” Embossed Melamine Sponge features three distinct layers which provide stability during rough scrubbing operations while its abrasive top sheet helps users maintain control through better grip even when the sponge becomes wet.

What Role Does Sponge Design Play in Abrasive Efficiency?

The design of melamine sponges determines their performance levels more than users understand because different designs function differently in different situations.

Effect of Embossed Texture on Friction Management

The embossed patterns on the surface of the sponge work to break up surface tension because they direct force pressure toward the raised ridges instead of distributing it uniformly across flat areas. The design pattern minimizes drag resistance while it helps to penetrate into the grooves where dirt accumulates.

Influence of Multi-Layer Structure on Pressure Distribution

The Multi-layer sponge design provides uniform force distribution across its surface area which helps users avoid fatigue during extended scrubbing tasks. The Tri-Layer “Sandwich” Embossed Melamine Sponge.

Impact of Density and Thickness on Water Retention and Release

Higher-density foams maintain water absorption for extended periods while preventing excessive dripping which makes them suitable for vertical installations such as shower walls and provide sufficient cushioning against pressure surges that protect sensitive finishes. High-quality products maintain a density range between 40-60kg/m³.

FAQ

Q1: What makes my magic eraser deteriorate at a fast rate?

A: The dry usage of the Magic Eraser produces excessive friction which shortens its lifespan because it operates better when used with damp conditions that provide smooth gliding.

Q2: What steps can I take to make my sponge last longer?

A: The sponge will last longer if you dry it immediately after cleaning and soak it in vinegar once a month and stay away from strong oxidizing agents.

Q3: What makes embossed designs unique?

A: The design pattern creates better contact efficiency through its raised elements which direct pressure and minimize drag when wiping.