Are There Hidden Risks When Using Magic Eraser Cleaning Sheets

2025-11-10

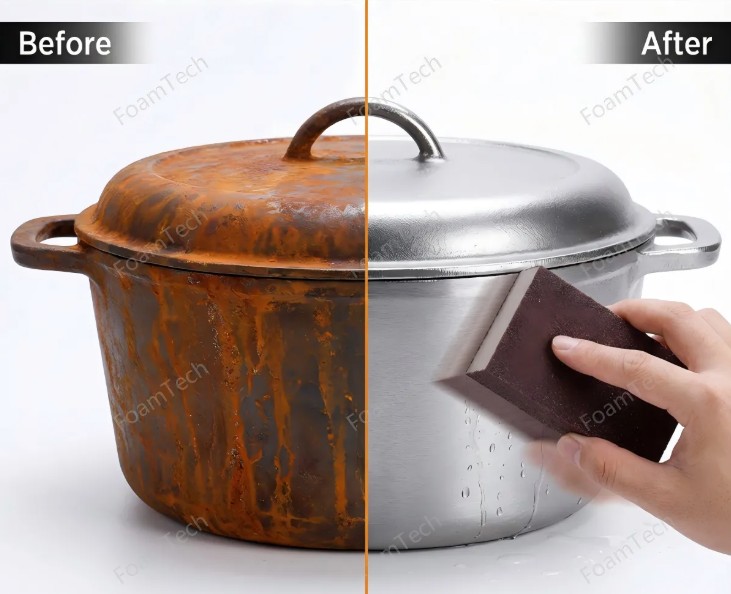

Households and industrial settings use Magic eraser cleaning sheets to remove stubborn stains and dirt because of their effectiveness. The cleaning process of these sheets requires only water because they do not need any dangerous chemicals. The safety profile of these products remains unclear despite their popularity. The melamine foam sheets used in these products create damage to sensitive surfaces when people use them incorrectly. People need to understand which surfaces to avoid using these products and the reasons behind this restriction.、

The company FoamTech operates as a primary supplier for high-performance melamine sponge products which serve cleaning needs across residential and commercial and industrial sectors.

Do Not Use Magic Eraser Cleaning Sheets Dry

The best results from Magic eraser cleaning sheets occur when users dampen them before use. The convenience of using dry Magic eraser sheets comes with a high risk of surface damage and reduced sponge lifespan.

Surface Damage from Abrasive Friction

The rigid structure of melamine foam becomes more abrasive when used dry because of its rigid microstructure. The abrasive nature of melamine foam when dry causes damage to surfaces that have paint or finished wood or glossy plastic coatings. The microstructure of melamine foam becomes more active when exposed to water which boosts its cleaning effectiveness and makes the process easier. The surface receives sanding treatment instead of dirt removal when you do not activate the foam.

Reduced Lifespan of the Cleaning Sheet

The practice of drying sponges leads to faster deterioration of their material. The foam material in the sponge deteriorates quickly when used multiple times until it loses its ability to clean effectively. The sponge needs to be soaked before cleaning but it should be dried immediately after cleaning to stop mold development. The correct usage sequence for sponges includes soaking them in water followed by gentle water removal and then wiping and cleaning before rinsing for future use.

Inefficient Cleaning Performance

The cleaning sheet achieves its magic through its open-cell structure which uses water activation to lift dirt particles through micro-abrasion. The cleaning process requires more force when you don't use water because it produces inferior results while extending your work duration and putting your surface at risk of damage.

Avoid Using on Electronic Screens and Displays

People often try to clean their phone screens and laptop displays with magic erasers because fingerprints do not come off easily. But don’t. The screens on these devices show greater sensitivity than their appearance indicates.

Risk of Micro-Scratches on Screen Coatings

The protective coatings on electronic screens include anti-glare and oleophobic layers. The application of melamine foam through light rubbing motions will create small scratches that damage the screen's visual quality. The screen suffers from rapid damage accumulation which results in permanent damage.

Potential for Moisture Intrusion into Devices

The edges and ports of screens become vulnerable to moisture when sponges contain even small amounts of water because phones and tablets with weak waterproofing systems will absorb this moisture. The presence of moisture in screens creates a danger for long-term damage through corrosion and electrical short circuits.

Incompatibility with Sensitive Display Materials

The sensitive layers of LCD and OLED screens become damaged when exposed to abrasion because they lack resistance against friction. The melamine sponge creates friction that damages pixel structures which results in unfixable permanent discoloration and dead spots that screen protectors cannot repair.

Not Suitable for Finished or Painted Wood Surfaces

The finished wood surface appears strong at first but its attractive appearance hides a thin protective coating system which serves both decorative and defensive purposes.

Removal of Protective Coatings or Finishes

The cleaning power of magic erasers makes them dangerous for use on varnished and lacquered surfaces. The cleaning power of Magic erasers removes paint and varnish and lacquer coatings from wooden surfaces. The wood surface becomes vulnerable to water damage and discoloration and structural changes after the protective coating is removed.

Uneven Color Fading on Treated Wood

The use of a magic eraser on stained furniture will produce irregular discolorations. The foam material in the product creates uneven pigment removal which results in spotty areas. The cleaning process produces more uneven discoloration than the original stain did.

Risk of Surface Etching and Roughness

The color will stay intact but multiple uses will create micro-abrasions which produce a rough texture. The surface becomes dull after repeated use because dirt particles find it harder to clean because of the rough texture.

Inappropriate for Polished or Glossy Surfaces

Glossy materials become dull on their surface when they encounter any type of abrasive substance no matter how gentle.

Loss of Shine and Reflectivity Over Time

The repeated use of a magic eraser on polished stone and chrome fixtures and glass surfaces will remove their glossy protective coating. The repeated application of this product will cause high-gloss finishes made from chrome and marble and glass to become dull.

Formation of Fine Scratches Under Light Exposure

The appearance of cleanliness under indoor lighting reveals multiple fine scratches when sunlight or direct light sources are applied. The scratches create visual disturbances which cannot be removed through polishing techniques.

Degradation of Surface Smoothness and Texture

The appearance and operational performance of polished surfaces depends on their uniform smoothness because glass tabletops and bathroom mirrors require this quality. The application of abrasive sponges leads to surface irregularities which attract dirt particles and cause the surface to lose its shine during extended use.

Are There Safer Alternatives for Delicate Surfaces?

The selection of appropriate cleaning products between them determines how well surface integrity remains intact during cleaning operations.

FoamTech’s Melamine Sponge Cleaning Sheet as a Controlled Option

The Melamine Sponge Cleaning Sheet from FoamTech features uniform density and small pores which create a balanced scrubbing effect. The vacuum foaming process enables the creation of pores that maintain 98% uniformity. The sponge provides delicate surface protection through its gentle touch while delivering outstanding cleaning results.

Solid-Color Magic Sponge Cleaning Sheet for Visual Monitoring

The Solid-Color Magic Sponge Cleaning Sheet allows users to track its usage patterns through its solid color design. The visual indicator on this product shows when to replace the sheet to prevent damage to sensitive areas.

Customization Services from FoamTech for Specific Applications

FoamTech develops customized solutions which take into account both material sensitivity and industry-specific requirements. The team at FoamTech connects your specific requirements to suitable formulations and density levels for both automotive detailing and high-end electronics manufacturing.

Can Magic Eraser Sheets Be Optimized for Industrial Use?

Yes—especially when manufactured using advanced processes designed for durability and compliance with industrial protocols.

Enhanced Durability in FoamTech’s Manufacturing Process

The proprietary compression system provides extended service life when users perform demanding cleaning operations. The system requires less replacement and generates less waste which results in improved long-term cost efficiency.

Compatibility with Industrial Cleaning Protocols and Standards

FoamTech produces products which fulfill all quality standards needed for commercial use. The EU REACH regulations SVHC substance test shows that FoamTech products contain no dangerous substances including formaldehyde and phthalates.

Bulk Supply and OEM Support from FoamTech’s Service Team

FoamTech enables worldwide procurement through its ability to produce foam products at scale and maintain international logistics networks. Their complete service offerings are available for review on their service page.

FAQ

Q1: Can I use magic eraser cleaning sheets on walls?

A: The product works only on walls with matte or semi-gloss paint finishes that lack decorative coatings but you should perform a small area test before application.

Q2: What happens if I use them dry?

A: The surface becomes more abrasive when used dry because it causes both the sponge and surface materials to deteriorate at a faster rate.

Q3: Are there any indicators which show when it becomes necessary to replace a sponge sheet?

A: Solid-color sheets with different colors enable users to track wear patterns which indicate when replacement becomes necessary.

Households and industrial settings use Magic eraser cleaning sheets to remove stubborn stains and dirt because of their effectiveness. The cleaning process of these sheets requires only water because they do not need any dangerous chemicals. The safety profile of these products remains unclear despite their popularity. The melamine foam sheets used in these products create damage to sensitive surfaces when people use them incorrectly. People need to understand which surfaces to avoid using these products and the reasons behind this restriction.、

The company FoamTech operates as a primary supplier for high-performance melamine sponge products which serve cleaning needs across residential and commercial and industrial sectors.

Do Not Use Magic Eraser Cleaning Sheets Dry

The best results from Magic eraser cleaning sheets occur when users dampen them before use. The convenience of using dry Magic eraser sheets comes with a high risk of surface damage and reduced sponge lifespan.

Surface Damage from Abrasive Friction

The rigid structure of melamine foam becomes more abrasive when used dry because of its rigid microstructure. The abrasive nature of melamine foam when dry causes damage to surfaces that have paint or finished wood or glossy plastic coatings. The microstructure of melamine foam becomes more active when exposed to water which boosts its cleaning effectiveness and makes the process easier. The surface receives sanding treatment instead of dirt removal when you do not activate the foam.

Reduced Lifespan of the Cleaning Sheet

The practice of drying sponges leads to faster deterioration of their material. The foam material in the sponge deteriorates quickly when used multiple times until it loses its ability to clean effectively. The sponge needs to be soaked before cleaning but it should be dried immediately after cleaning to stop mold development. The correct usage sequence for sponges includes soaking them in water followed by gentle water removal and then wiping and cleaning before rinsing for future use.

Inefficient Cleaning Performance

The cleaning sheet achieves its magic through its open-cell structure which uses water activation to lift dirt particles through micro-abrasion. The cleaning process requires more force when you don't use water because it produces inferior results while extending your work duration and putting your surface at risk of damage.

Avoid Using on Electronic Screens and Displays

People often try to clean their phone screens and laptop displays with magic erasers because fingerprints do not come off easily. But don’t. The screens on these devices show greater sensitivity than their appearance indicates.

Risk of Micro-Scratches on Screen Coatings

The protective coatings on electronic screens include anti-glare and oleophobic layers. The application of melamine foam through light rubbing motions will create small scratches that damage the screen's visual quality. The screen suffers from rapid damage accumulation which results in permanent damage.

Potential for Moisture Intrusion into Devices

The edges and ports of screens become vulnerable to moisture when sponges contain even small amounts of water because phones and tablets with weak waterproofing systems will absorb this moisture. The presence of moisture in screens creates a danger for long-term damage through corrosion and electrical short circuits.

Incompatibility with Sensitive Display Materials

The sensitive layers of LCD and OLED screens become damaged when exposed to abrasion because they lack resistance against friction. The melamine sponge creates friction that damages pixel structures which results in unfixable permanent discoloration and dead spots that screen protectors cannot repair.

Not Suitable for Finished or Painted Wood Surfaces

The finished wood surface appears strong at first but its attractive appearance hides a thin protective coating system which serves both decorative and defensive purposes.

Removal of Protective Coatings or Finishes

The cleaning power of magic erasers makes them dangerous for use on varnished and lacquered surfaces. The cleaning power of Magic erasers removes paint and varnish and lacquer coatings from wooden surfaces. The wood surface becomes vulnerable to water damage and discoloration and structural changes after the protective coating is removed.

Uneven Color Fading on Treated Wood

The use of a magic eraser on stained furniture will produce irregular discolorations. The foam material in the product creates uneven pigment removal which results in spotty areas. The cleaning process produces more uneven discoloration than the original stain did.

Risk of Surface Etching and Roughness

The color will stay intact but multiple uses will create micro-abrasions which produce a rough texture. The surface becomes dull after repeated use because dirt particles find it harder to clean because of the rough texture.

Inappropriate for Polished or Glossy Surfaces

Glossy materials become dull on their surface when they encounter any type of abrasive substance no matter how gentle.

Loss of Shine and Reflectivity Over Time

The repeated use of a magic eraser on polished stone and chrome fixtures and glass surfaces will remove their glossy protective coating. The repeated application of this product will cause high-gloss finishes made from chrome and marble and glass to become dull.

Formation of Fine Scratches Under Light Exposure

The appearance of cleanliness under indoor lighting reveals multiple fine scratches when sunlight or direct light sources are applied. The scratches create visual disturbances which cannot be removed through polishing techniques.

Degradation of Surface Smoothness and Texture

The appearance and operational performance of polished surfaces depends on their uniform smoothness because glass tabletops and bathroom mirrors require this quality. The application of abrasive sponges leads to surface irregularities which attract dirt particles and cause the surface to lose its shine during extended use.

Are There Safer Alternatives for Delicate Surfaces?

The selection of appropriate cleaning products between them determines how well surface integrity remains intact during cleaning operations.

FoamTech’s Melamine Sponge Cleaning Sheet as a Controlled Option

The Melamine Sponge Cleaning Sheet from FoamTech features uniform density and small pores which create a balanced scrubbing effect. The vacuum foaming process enables the creation of pores that maintain 98% uniformity. The sponge provides delicate surface protection through its gentle touch while delivering outstanding cleaning results.

Solid-Color Magic Sponge Cleaning Sheet for Visual Monitoring

The Solid-Color Magic Sponge Cleaning Sheet allows users to track its usage patterns through its solid color design. The visual indicator on this product shows when to replace the sheet to prevent damage to sensitive areas.

Customization Services from FoamTech for Specific Applications

FoamTech develops customized solutions which take into account both material sensitivity and industry-specific requirements. The team at FoamTech connects your specific requirements to suitable formulations and density levels for both automotive detailing and high-end electronics manufacturing.

Can Magic Eraser Sheets Be Optimized for Industrial Use?

Yes—especially when manufactured using advanced processes designed for durability and compliance with industrial protocols.

Enhanced Durability in FoamTech’s Manufacturing Process

The proprietary compression system provides extended service life when users perform demanding cleaning operations. The system requires less replacement and generates less waste which results in improved long-term cost efficiency.

Compatibility with Industrial Cleaning Protocols and Standards

FoamTech produces products which fulfill all quality standards needed for commercial use. The EU REACH regulations SVHC substance test shows that FoamTech products contain no dangerous substances including formaldehyde and phthalates.

Bulk Supply and OEM Support from FoamTech’s Service Team

FoamTech enables worldwide procurement through its ability to produce foam products at scale and maintain international logistics networks. Their complete service offerings are available for review on their service page.

FAQ

Q1: Can I use magic eraser cleaning sheets on walls?

A: The product works only on walls with matte or semi-gloss paint finishes that lack decorative coatings but you should perform a small area test before application.

Q2: What happens if I use them dry?

A: The surface becomes more abrasive when used dry because it causes both the sponge and surface materials to deteriorate at a faster rate.

Q3: Are there any indicators which show when it becomes necessary to replace a sponge sheet?

A: Solid-color sheets with different colors enable users to track wear patterns which indicate when replacement becomes necessary.